Key Takeaways:

- Understand the complex process of hard rock mining from site exploration to ore extraction.

- Learn about the various mining methods and equipment used in hard rock mines.

- Discover the environmental considerations and safety protocols in place for hard rock mining operations.

Hard rock mining is a fascinating and complex process that involves extracting valuable materials from solid rock beneath the earth's surface. This article will delve into the intricacies of how hard rock mining works, the equipment used, and the safety measures in place to protect miners and the environment.

The Basics of Hard Rock Mining

Hard rock mining is the process of extracting metals and minerals encased in rocks. Unlike surface mining, where materials are more readily accessible, hard rock mining requires digging deep underground to reach the ore deposit.

This type of mining is necessary for obtaining substances such as gold, silver, iron, copper, zinc, nickel, tin, and lead, which are often found in conjunction with other minerals.

Exploration: The First Stage

Before any mining can occur, extensive exploration is necessary to locate a viable ore body. Geologists use a variety of methods, including satellite imagery, geological surveys, and exploratory drilling, to identify potential mine sites.

Once an ore deposit is found, the next slice of work involves determining whether it contains enough gold or other minerals to make mining economically feasible.

Drilling and Blasting: Breaking the Earth

Once a site is deemed suitable, the mining process begins with drilling and blasting. Hard rock miners use specialized equipment to drill holes into the surrounding rock.

Explosives are then placed into these holes and detonated, creating smaller pieces of rock that can be more easily handled and processed. This is a carefully controlled process to ensure low ore loss and low dilution.

Underground Mining: Accessing the Ore

Underground mining is a selective mining method cut out for accessing ore deposits deep within the earth. Miners create a network of tunnels and shafts to reach the ore.

Techniques like vertical retreat mining and pillar mining are employed to extract gold and other minerals from vertical zones and steeply dipping orebodies while maintaining a strong roof rock for safety.

Crushing and Grinding: From Rocks to Sand

After the ore is brought to the surface, it must be processed to extract the valuable material. The first step is crushing the ore into smaller pieces using a jaw crusher.

The crushed ore is then ground into a fine sand-like consistency in a ball mill. This process is essential for separating the valuable minerals from the waste rock.

Selective Mining Methods: Precision in Extraction

Have you ever wondered how miners decide where to dig and what to leave behind? Selective mining methods are the answer.

These methods allow miners to extract ore from primary and secondary stopes with precision, ensuring that the valuable material is removed while minimizing the disturbance to the surrounding environment.

By using a pre-planned sequence, miners can target the ore deposits accurately, reducing waste and increasing efficiency.

In practice, selective mining involves a careful analysis of the ore body. Techniques such as cut and fill or room and pillar mining are employed to maintain wall support and manage the large void left after the extraction.

The ore is broken up in a regular pattern, with side chambers and caving stops designed to keep the mine stable. This method is particularly useful in complex geological conditions where the same techniques used in open pit mines might not be feasible. Selective Mining Methods Cut: A Targeted Approach Selective mining methods are revolutionizing the way we extract valuable minerals from the earth.

By employing a pre-planned sequence of extraction, these methods ensure that only the ore with the highest concentration of valuable minerals is removed. This targeted approach not only maximizes the yield of resources but also minimizes waste and environmental impact.

It's a strategic game of precision, where every cut and blast is carefully calculated to optimize the mining process.

The beauty of selective mining methods cut lies in its ability to adapt to the unique geological conditions of each mine. By using advanced mapping technologies and real-time data analysis, miners can identify the most lucrative ore pockets and plan their extraction sequence accordingly.

This methodical approach ensures that the ore is mined efficiently, reducing the need for excessive processing and refining. It's a smarter, cleaner way to mine that's gaining traction in the industry.

Pre-Planned Sequence: The Blueprint of Mining Efficiency When it comes to hard rock mining, a pre-planned sequence is the backbone of operational efficiency. Before a single drill pierces the earth's crust, mining engineers meticulously design the sequence of operations.

This blueprint dictates every phase of the mining process, from the initial drilling to the final ore extraction. It's a complex puzzle that requires foresight and precision, ensuring that each step seamlessly leads to the next.

The implementation of a pre-planned sequence in mining operations is akin to a well-rehearsed symphony. Each miner and machine plays a specific part at a precise moment, creating a harmonious flow of productivity.

This level of planning reduces downtime, optimizes resource allocation, and enhances safety measures.

By sticking to the script, miners can navigate the unpredictable nature of underground mining with confidence and control, ensuring that the ore is mined with maximum efficiency and minimal disruption.

Pre-Planned Sequence: The Blueprint of Mining Operations

When we talk about a pre-planned sequence in the context of hard rock mining, we're referring to the meticulously organized steps that ensure the mining process is efficient, safe, and environmentally responsible.

This isn't a simple dig-and-go operation; it's a complex dance choreographed long before the first drill pierces the earth.

Mining engineers and geologists work together to develop a mining plan that dictates the order of operations, from exploration to ore extraction and waste management. This plan is crucial because it helps to minimize risks and optimize the recovery of valuable minerals.

The pre-planned sequence is akin to a roadmap for the entire mining project. It includes the identification of the ore body, the method of mining to be employed, the design of the mine layout, and the schedule for each phase of the mining process.

By adhering to this sequence, miners can ensure that they are not only extracting resources in the most logical and efficient manner but also maintaining the integrity of the mine structure and surrounding environment.

It's a strategic approach that balances economic gain with ecological and safety considerations, setting the stage for a successful mining operation.

The Significance of a Pre-Planned Sequence in Hard Rock Mining

When we talk about hard rock mining, the term "pre-planned sequence" isn't just industry jargon; it's the backbone of the entire operation. Imagine orchestrating a ballet of heavy machinery, where each move is meticulously choreographed to ensure efficiency and safety.

That's what a pre-planned sequence in mining is all about. It involves the strategic planning of when and where to drill, blast, and extract the ore, considering the geological conditions and the end goal of minimizing waste and maximizing resource recovery.

A pre-planned sequence is not only about the order of operations but also about the precise timing. It's a complex puzzle where each piece must fit perfectly to avoid costly delays or dangerous mishaps.

For instance, drilling patterns are designed to optimize the fragmentation of the rock, which in turn affects the efficiency of subsequent blasting and ore extraction.

By adhering to a pre-planned sequence, miners can reduce the environmental impact and ensure that the valuable ore is not diluted with unwanted material, thereby enhancing the overall profitability of the mine.

Pre-Planned Sequence: The Role in Risk Management

In the realm of hard rock mining, risk management is paramount, and a pre-planned sequence is a critical tool in the miner's kit.

This sequence is not just about the order of operations; it's a comprehensive plan that encompasses all aspects of the mining process, from the initial surveying and sampling to the final stages of ore processing.

By following a pre-planned sequence, miners can anticipate potential hazards and implement measures to mitigate them, ensuring the safety of the workforce and the integrity of the mining site.

Moreover, a pre-planned sequence allows for the continuous monitoring and adjustment of mining activities. As the mining progresses, new information may come to light, necessitating changes to the plan.

This flexibility is crucial in managing the inherent uncertainties of mining, such as unexpected geological formations or equipment failures.

By having a robust pre-planned sequence in place, miners can adapt to these challenges swiftly and effectively, minimizing disruptions and maintaining a steady pace towards the successful extraction of valuable minerals.

The Economic Impact of Mining: Beyond the Ore

Hard rock mining is a powerhouse of economic activity, and its impact extends far beyond the extraction of minerals. The industry creates jobs, not just for those working directly in the mines, but also for those in related sectors such as equipment manufacturing, transportation, and environmental management.

The ripple effect of mining on the economy can be profound, with local communities often experiencing a surge in employment and business opportunities. This economic stimulation is a vital aspect of why mining projects are so carefully evaluated before they begin.

However, it's not just about job creation. The minerals and metals extracted from hard rock mines are essential components in various industries, from construction and electronics to renewable energy technologies.

For instance, lithium and cobalt are critical for battery production in electric vehicles, which are pivotal in the transition to a greener economy. The economic impact of mining, therefore, is twofold: it contributes to immediate economic growth and plays a crucial role in enabling future technologies that can lead to sustainable development.

Understanding this broader economic context is essential when considering the full scope of hard rock mining's significance.

The Anatomy of a Mine: Understanding Mine Shafts and Haulage Access

Delving deeper into the structure of hard rock mines, let's talk about mine shafts and haulage access. These are the lifelines of an underground miner, providing a path to the depths where the broken ore awaits.

A vertical shaft is often the most direct route to the deep-seated ore, equipped with lifts for transporting miners and ore to and from the surface. It's like an elevator to the underworld, with the added thrill of potential riches.

Haulage access refers to the network of tunnels that connect different parts of the mine, including the primary stopes. These tunnels are meticulously planned to allow for the safe and efficient transport of ore.

Imagine a subway system, but instead of trains, there are heavy-duty trucks and loaders moving through the glory hole—a term for a large excavation opening in a mine.

This network ensures that the ore can be moved to the surface for processing in a systematic and controlled manner, following the same techniques for safety and efficiency as seen in other engineering marvels.

Gravity Separation: Sifting the Valuable from the Worthless

The next stage in the mining process involves separating the valuable minerals from the sand. Gravity separation is a common method used to achieve this.

The principle behind this technique is that valuable minerals are typically denser than the surrounding rock and can be separated by their different rates of settling in water.

Tailings Ponds: Managing Mining Waste Rock

The waste rock, or tailings, produced during the mining process is stored in tailings ponds. These ponds are designed to contain the byproducts of mining and prevent them from contaminating the surrounding environment.

The management of tailings ponds is a critical aspect of hardrock mining, as a massive collapse or leakage could have devastating consequences.

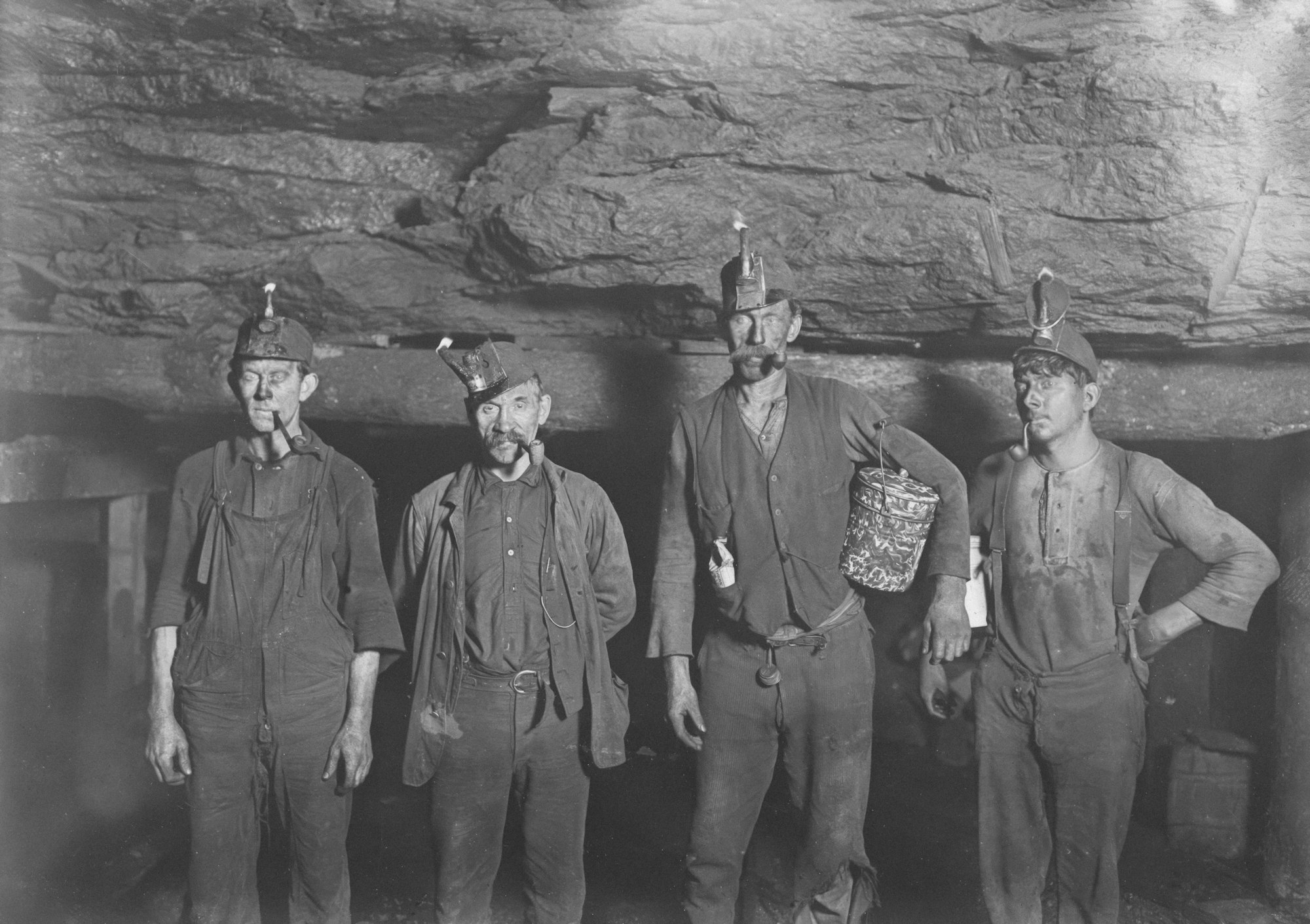

Safety Protocols: Protecting the Miners

Safety is paramount in hard rock mines. Underground miners are equipped with safety equipment and must follow strict safety protocols to prevent accidents.

Regular training and drills ensure that miners are prepared for emergencies, such as caving rock or other hazardous situations that may occur deep within the mine.

Environmental Considerations: A Sustainable Approach

Hard rock mining has a significant impact on the environment. To mitigate this, many mines implement practices such as hydraulic fracturing and cemented fill to minimize the disturbance to the surrounding rock.

Additionally, reclamation efforts are made to restore the mine site after operations have ceased, aiming for a delayed return of the area to its natural state.

The Role of Technology: Innovations in Mining

Advancements in technology have revolutionized the hard rock mining industry. From the development of more efficient drilling equipment to the use of computer modeling for mine planning, technology has made mining safer and more cost-effective.

Innovations like vertical crater retreat and the fill method have also allowed miners to access irregular ore zones with less ore loss.

The Future of Hard Rock Mining

As the demand for minerals continues to grow, so does the need for efficient and sustainable mining practices. The future of hard rock mining lies in the adoption of new technologies and the continuous improvement of existing methods.

With a focus on reducing environmental impact and enhancing safety, the industry is evolving to meet the challenges of the 21st century.

Some Final Thoughts

Hard rock mining is a critical industry that supplies the world with essential minerals. From exploration to extraction, the process is complex and requires a combination of advanced technology, skilled labor, and strict safety and environmental protocols.

As we've explored, the journey from solid rock to valuable material is a fascinating one, involving various stages such as drilling, blasting, crushing, and separation.

With the ongoing advancements in mining technology and practices, the industry continues to strive for more efficient and environmentally responsible methods.

FAQ's

What is hard rock mining?

Hard rock mining is the process of extracting metals and minerals like gold, silver, and copper from solid rock formations underground. It involves various stages, including exploration, drilling, blasting, and processing of the ore to extract the valuable materials.

What are some common mining methods used in hard rock mines?

Common mining methods include underground mining techniques such as vertical retreat mining, pillar mining, and selective mining methods that target vertical zones and steeply dipping orebodies. These methods are chosen based on the geology of the ore deposit and the surrounding rock.

How do miners ensure safety in hard rock mines?

Safety in hard rock mines is ensured through the use of safety equipment, regular training, and adherence to strict safety protocols. Miners are trained to handle emergencies, and measures are in place to prevent accidents such as caving rock or other hazardous situations.

Member discussion