Gold prospecting is an adventure that combines the thrill of the hunt with the serene beauty of nature. Among the various methods to extract this precious metal, sluicing for gold stands out as both a nod to historical mining techniques and a preferred method for modern prospectors.

This article dives into the nuts and bolts of sluicing, exploring how it works, the equipment used, and tips for maximizing your gold recovery.

As a recreation miner myself, I found that over time, just using a pan to sort through material became a bit time consuming. If the regulations in your area permit, moving up to a sluice box will increase production and allow you to find more gold. There are so many sizes of sluice boxes to fit your needs. Get one and try it out!

What is Sluicing?

Sluicing for gold is a process that uses a sluice box, a long, narrow box often made from aluminum or wood, to separate gold from other materials using water flow and gravity.

The basic idea is simple: gold-bearing gravel is shoveled into the sluice box where the heavier gold particles settle to the bottom and are trapped by riffles, while the lighter material is washed away.

The efficiency of sluicing comes from its ability to process a large amount of material quickly. Unlike gold panning, which is slower and primarily used for sampling, sluicing can handle tons of gravels, increasing the chances of recovering more gold.

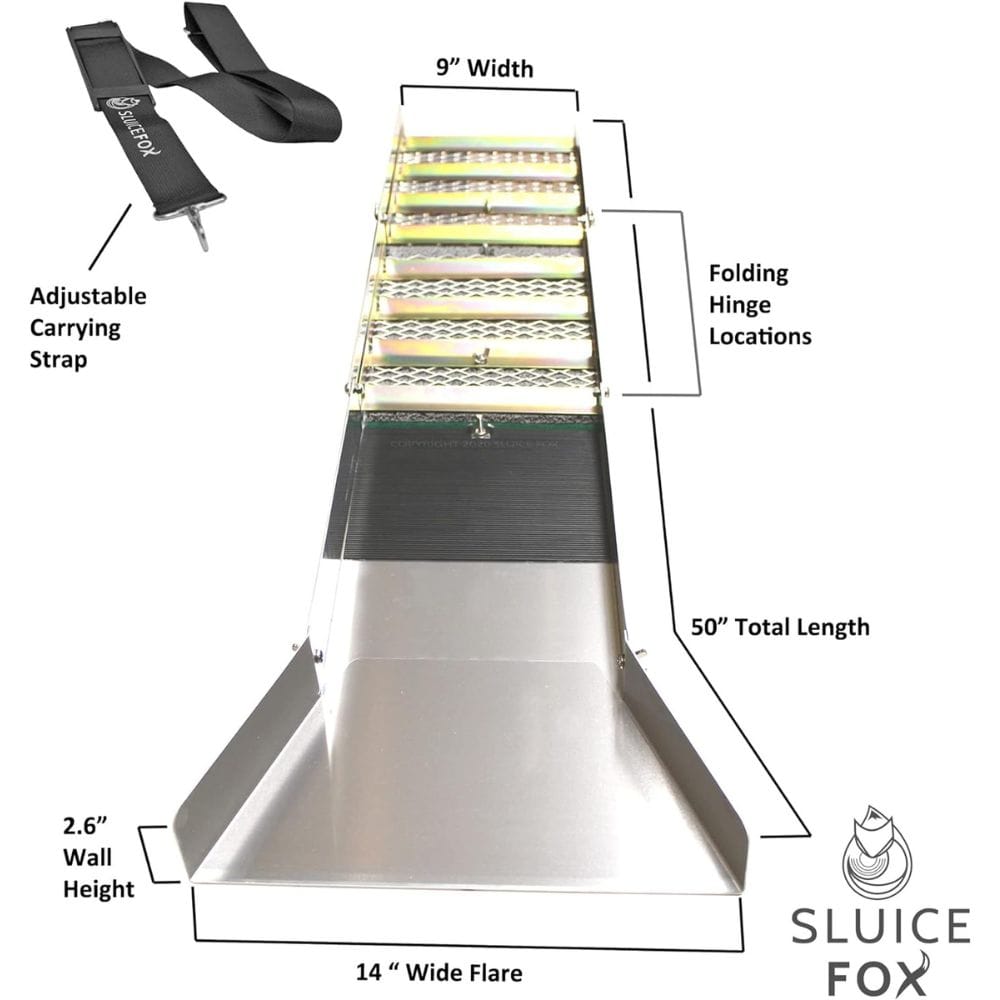

The Anatomy of a Sluice Box

A typical sluice box is outfitted with several key features designed to maximize the recovery of fine gold. The box itself is usually set at a gentle incline, allowing water to push the material over the riffles where gold is caught.

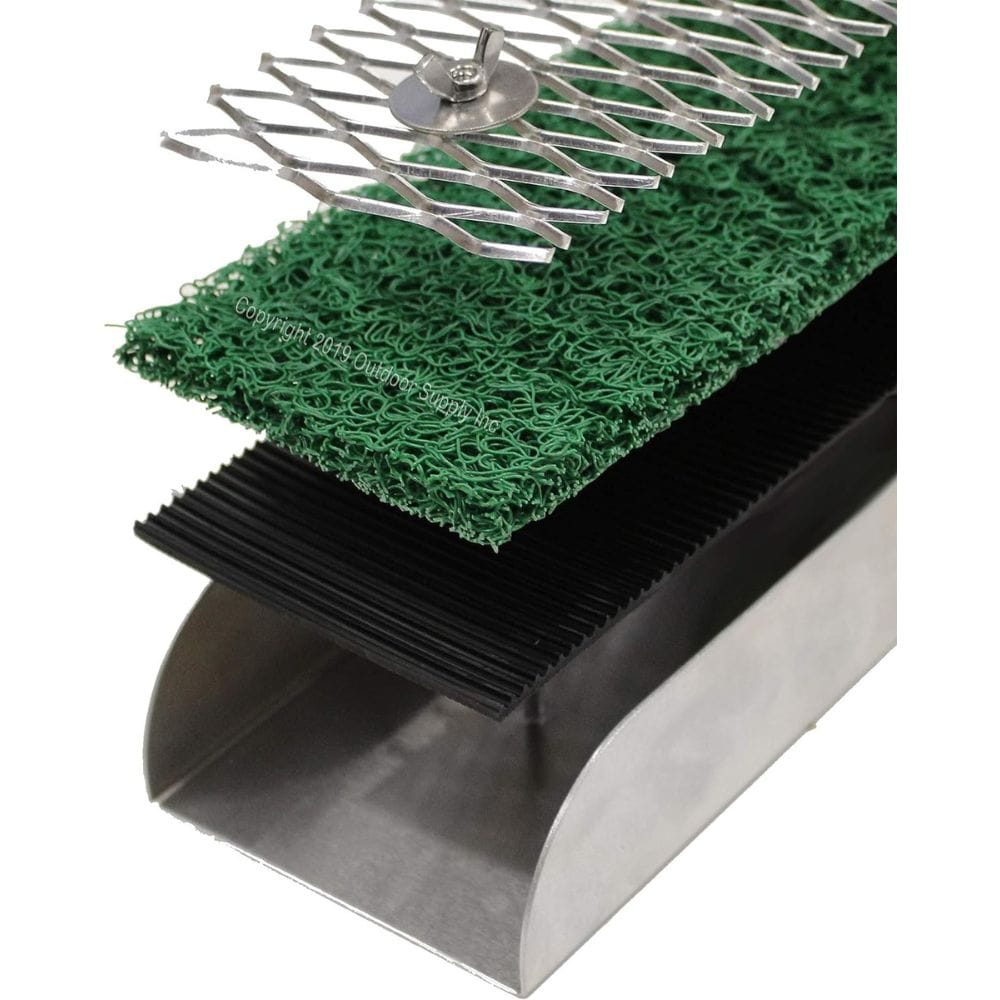

The surface of the sluice may be lined with ribbed carpet or miner's moss, which helps trap the finer particles of gold that might otherwise be lost.

Riffles are the metal bars running across the width of the sluice box. These create low pressure pockets where heavier gold can settle as lighter sands and gravels are washed over them. The design and spacing of riffles play a crucial role in the sluice’s effectiveness.

Setting Up Your Sluice Box

Proper placement and angle of your sluice box are critical for optimal gold recovery. The sluice should be positioned in a part of the stream with a strong current that can carry the feed material through the box.

The angle of inclination should be such that the water runs fast enough to carry away the lighter material but slow enough to allow gold to settle.

It's also essential to ensure that the sluice box is stable and won't be carried away or tipped over by the flow of the river. Some prospectors use rocks or boulders to secure the sluice in place.

The Role of Black Sand in Gold Sluicing

Black sand, often a signal to seasoned miners that they're in the right neighborhood, plays a crucial role in the process of sluicing for gold. This dense material is primarily composed of iron oxides and can be a gold-bearing gravel's constant companion.

When sluicing, the heavier black sand and gold descend to the bottom of the sluice box, allowing for more effective gravity separation. This natural sorting helps prospectors focus their efforts on the areas most likely to contain gold, rather than wasting time on less promising materials.

Moreover, understanding how to manage black sand can significantly increase the efficiency of gold recovery. During the washing process, as water carries the lighter materials downstream, black sand typically accumulates around the riffle areas.

This accumulation can act as a gold trap, catching and holding the heavier gold particles. Early prospectors quickly learned to watch for these black sand deposits as indicators of potential gold-rich areas, a practice that remains relevant among modern enthusiasts.

Enhancing Gold Recovery with Proper Riffle Design

The design of the riffles in a sluice box is more than just a structural necessity; it's a fine-tuned aspect of gold recovery. Riffles are essentially small barriers placed across the bottom of a sluice that catch heavier materials like gold as lighter rocks and sediment are washed away.

The effectiveness of these riffles directly influences how much gold can be recovered from gold-bearing gravel. Each riffle creates a low-pressure zone behind it, where gold particles can settle out of the free flow of water and accumulate.

Choosing the right riffle design can be as much an art as it is a science. Miners have experimented with various shapes and sizes of riffles to maximize gold capture.

Streamlined designs allow for a smoother flow of water and materials, reducing the chance of gold being lifted and carried away with tailings. This careful balance between flow rate and material retention is critical, especially in areas where gold particles are finer and more difficult to catch.

By optimizing riffle design, miners can ensure that more gold is trapped and less is lost to the streams.

Operating Techniques

Feeding the sluice box efficiently is key to successful gold recovery. Material should be added gradually and evenly to avoid overwhelming the sluice. It’s important to break up clumps of clay or dirt before they are fed into the sluice to ensure that all potential gold is freed and can be captured.

Regularly clearing the riffles and checking the ribbed carpet for accumulations of heavy black sands and gold is also crucial. This prevents the sluice from becoming overloaded, which can cause gold to be swept away with the tailings.

Cleaning and Collecting Gold

Once you've run material through the sluice, the next step is cleaning out the sluice box to collect the gold. This usually involves carefully removing the riffles and miner's moss, washing them into a bucket, and then processing the remaining material with a gold pan.

The panning process helps separate the gold from the lighter sands and gravels that were also trapped in the sluice.

The excitement of seeing the shiny specks of gold in the bottom of your pan is unmatched, providing a rewarding payoff for your hard work and patience.

Common Mistakes to Avoid

Newcomers to sluicing often make a few common mistakes. One is not setting the sluice at the correct angle, which can either cause gold to be lost or the sluice to clog with materials.

Another mistake is not sorting out larger rocks and debris before they are fed into the sluice, which can damage equipment or hinder the separation process.

By paying attention to these details, you can avoid frustration and improve your gold recovery rates.

Some Final Thoughts

Sluicing for gold is an effective and exciting way to prospect for gold. By understanding how to set up and operate a sluice box correctly, and by paying attention to the nuances of the process, you can significantly increase your chances of success. Whether you're a seasoned miner or a curious newcomer, the world of sluicing offers a fascinating glimpse into the age-old quest for gold.

FAQ's

Q1: How do I choose the right location to set up my sluice box? A1: Look for areas in the creek or river where water flows steadily and with enough force to move gravels. Avoid places with low water flow, as they may not provide enough force to properly operate the sluice.

Q2: What is the best angle to set my sluice box at? A2: The ideal angle varies depending on the water flow and material, but generally, a 5 to 15-degree downhill tilt is effective. Experimenting with different angles can help determine what works best for your specific situation.

Q3: How often should I clean out my sluice box? A3: This depends on how much material you are processing and the gold concentration in the soil. As a general rule, check the sluice every hour or so to ensure it's not clogged and to assess if the riffles are catching gold effectively.

Member discussion